Advanced Drill Case Study

Overview

This innovative drill is engineered to withstand wet weather conditions and ensure comfortable, prolonged usage, making it an ideal tool for carpenters. Traditional drills often suffer from water damage and fatigue due to their weight. In contrast, this drill is lightweight, durable, and water-resistant. Advanced ergonomic handles and a 30V lithium-ion battery provide reliable torque, ensuring compliance with stringent safety standards for global distribution. With USB charging ports and a 110V socket, the drill offers versatile connectivity.

Although it is not intended for the average consumer due to its specialized features and cost, this tool is a strategic solution for carpenters seeking long-term reliability, powerful performance, and enhanced ergonomics. This robust drill can address the unique challenges professionals face in demanding environments where snow, humidity, and confined spaces are daily challenges.

Introduction

Carpenters and other professionals often work in challenging environments where tools are exposed to the elements, and long hours are standard. The demand for a durable, reliable, and ergonomic drill is high. This drill is purpose-built to meet those requirements, ensuring resistance to wet conditions and comfortable usage over long periods. Innovative water-resistant technologies, ergonomic features, and high-performance components ensure that the drill effectively tackles key pain points for professionals.

Its powerful 30V lithium-ion battery, sealed with silicone and epoxy for water resistance, ensures robust torque without compromising durability or safety. USB ports and a 110V socket offer versatile charging capabilities. By understanding the challenges faced by carpenters and designing the drill to meet their needs, this tool is poised to redefine professional-grade reliability. Whether in snow, rain, or during extended hours, this drill provides unmatched performance and convenience.

Problem Statement

Conventional drills often face internal damage due to water exposure and are bulky and uncomfortable for prolonged use. Their design makes them prone to fatigue, particularly in high-demand applications.

The Challenge

The challenge is to design a powerful, lightweight drill to assist carpenters. It should be engineered for heavy usage over long hours and offer durability against drops and impacts. Water resistance is crucial for carpenters working in cold climates where snow and humidity can be problematic.

Ergonomic Needs

The drill’s size can be inconvenient for confined spaces, and while the handles are comfortable, further weight reduction is needed. An ergonomic grip is essential, as prolonged use can lead to fatigue. The design must accommodate both men’s and women’s needs for grip and comfort.

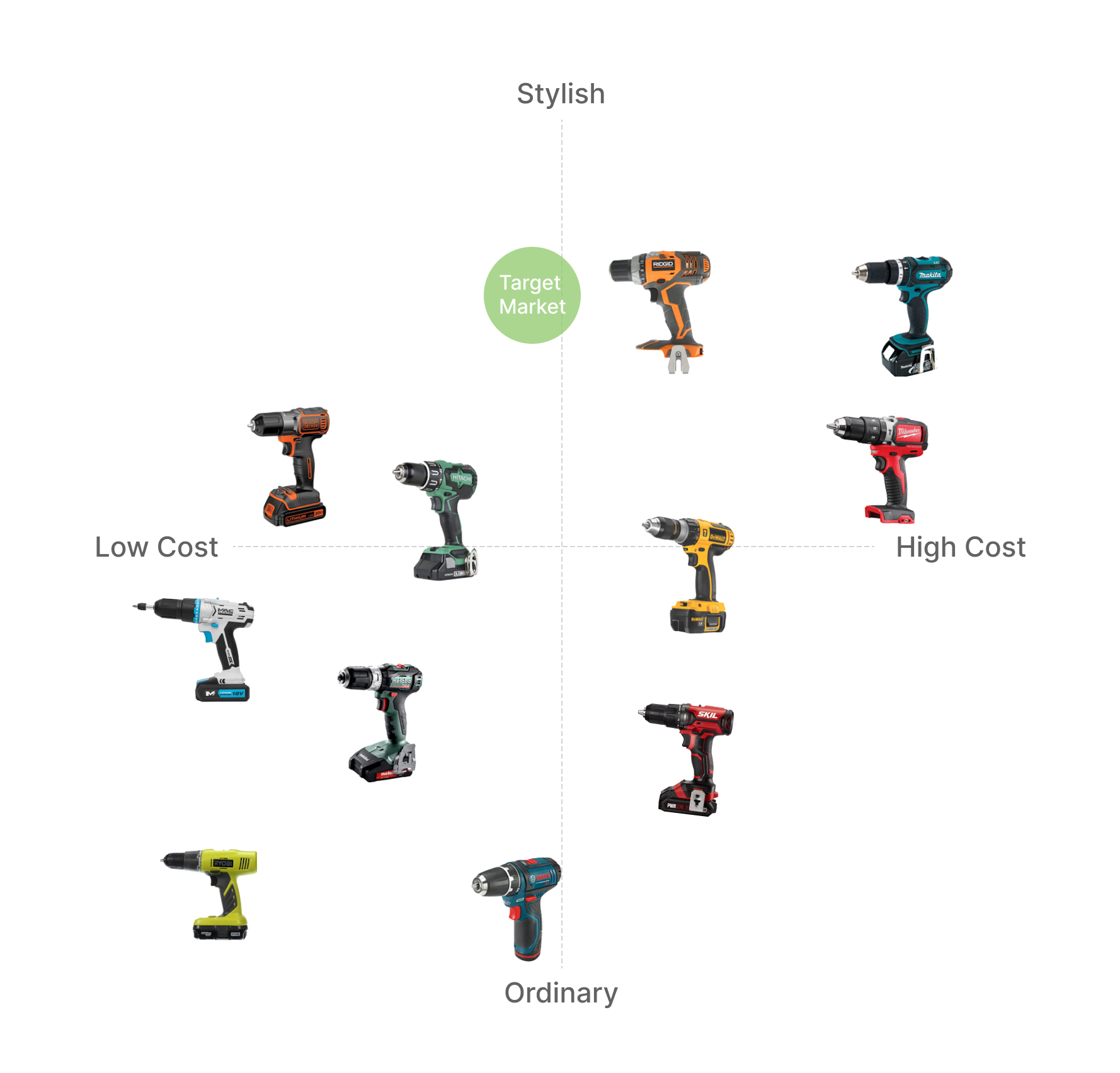

Competition

While the market has some existing solutions, there is a noticeable lack of a highly customizable modular bag catering specifically to kayak anglers’ needs. This represents a golden opportunity to establish a unique selling proposition and gain a competitive edge by introducing a superior and tailored product.

Market Needs

This drill caters to a broad range of users across occupations, with carpenters being the primary target audience due to its specific features. Although it is not the most affordable option for the general user, it will offer exceptional quality and availability at hardware stores and online.

Competitive Landscape

The competition is intense, with many experienced brands in this product category. The key competitive characteristics include long-lasting power, an ergonomic design, powerful gears, and water-proof components.

The Technology

The drill operates on a 30V lithium-ion battery, providing substantial torque. USB ports and a 110V socket add versatile connectivity. Silicone and epoxy seal the internal components to protect against water damage.

Safety Regulations

To meet safety standards, the drill requires UL certification and cUL approval for Canada distribution. CE certification will also be necessary for European markets.

Materials and Processes

The drill is constructed using high-quality materials like plastic, silicone, rubber, metal, and aluminum. Aluminum forms the internal structure, plastic acts as a filler, silicone provides waterproofing, and metal is used for gear components.

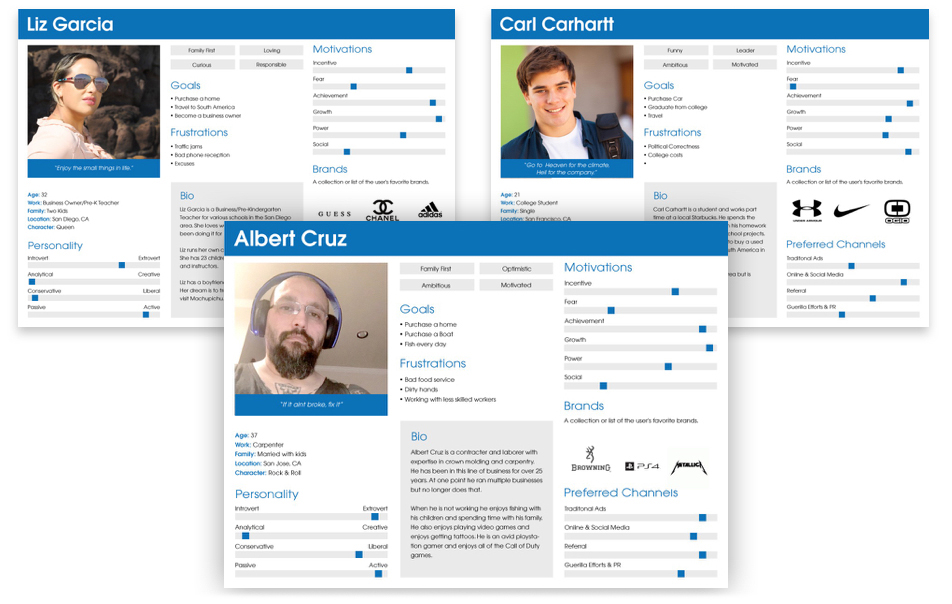

Target Market & Research

Research indicates that professional carpenters are the primary market for this product. Its higher cost and specialized features are tailored for carpentry needs, making it unsuitable for students or small business owners. By strategically focusing on the carpenter demographic, the product is well-positioned to meet specific demands, leading to market success.

Demographics

- Age Range: Carpenters span a wide age range, with individuals entering the profession as young as 18 and continuing well into their late 60s or beyond. The majority of carpenters fall within the 25 to 54 age group, representing the core workforce in the carpentry industry.

- Gender: Historically, carpentry has been a male-dominated field. However, in recent years, there has been a gradual increase in the number of female carpenters, reflecting a more diverse workforce.

- Education Level: Carpenters typically require a high school diploma or equivalent to enter the profession. While some pursue formal training or apprenticeships, others gain experience through on-the-job training and hands-on work.

- Income Level: The income of carpenters varies based on factors such as experience, specialization, and geographic location. Generally, skilled and experienced carpenters tend to earn higher incomes, particularly those working in urban areas or specializing in niche markets.

- Employment Status: Carpenters can be employed in various capacities, including self-employed, working for construction companies, contractors, or in the manufacturing industry. Self-employment is common among experienced carpenters seeking greater flexibility and autonomy.

- Geographic Location: Carpenters are found in both urban and rural areas, depending on construction demands and economic factors. Urban centers with active construction industries often have a higher concentration of carpenters.

- Work Environment: Carpenters work in a variety of settings, from construction sites to workshops and clients’ locations. Some may focus on residential projects, while others work in commercial or industrial settings.

- Specialization: Carpenters can specialize in various areas, such as rough carpentry, finish carpentry, or cabinetmaking. Specialization may influence their tool and equipment preferences.

- Tech Savviness: With advancements in construction technology, carpenters are increasingly adopting digital tools and software for design, measurement, and project management.

- Work Experience: The level of experience varies widely among carpenters, from entry-level apprentices to highly experienced master carpenters with decades of expertise.

Pain Points

-

John (User A): “I love the convenience of a wireless drill, but my biggest frustration is the battery life. It always seems to die on me right in the middle of a project! Need a reliable drill that lasts longer!”

- Emma (User B): “Wireless drills are great, but I wish they were lighter. My current one feels like a workout after extended use. A lightweight option would be a game-changer!”

- Michael (User C): “I’ve had a few wireless drills, and they all suffer from overheating issues. It slows down my work progress and worries me about damaging the drill. Need a more efficient cooling system!”

- Sarah (User D): “One of the challenges with wireless drills is finding a suitable storage solution for all the accessories. I keep misplacing drill bits, and it’s frustrating. An organized drill kit would be fantastic!”

- Alex (User E): “The lack of power in some wireless drills is disappointing. I need something with enough torque to handle tough tasks without stalling. A powerful wireless option would be a dream come true!”

- Robert (User F): “Weather-resistant drills are essential for me as I often work outdoors. My current wireless drill struggles in rainy conditions. An all-weather design would save me a lot of trouble!”

- Olivia (User G): “I wish there was a wireless drill with smart features. Like an app to monitor battery life and receive maintenance reminders. A drill that’s tech-savvy would be a huge plus!”

- Daniel (User H): “Wireless drills are great for portability, but they can be quite noisy. A quieter option would be fantastic, especially when working in shared spaces!”

- Sophia (User I): “Changing drill bits can be tedious and time-consuming with my current wireless drill. A quick and easy bit-changing mechanism would save me so much hassle!”

- Matthew (User J): “I often work in tight spaces, and my current wireless drill is too bulky to maneuver comfortably. A compact design with the same power would be a total game-changer for me!”

Target Matrix

My innovative drill is marked with a green indicator. This is the ideal positioning and reflects my strategic emphasis on providing a premium yet stylish tool that balances quality with affordability. Compared to the 11 common drills placed around the matrix, my drill stands out by uniquely offering carpenters an elevated blend of style, cost-effectiveness, and advanced functionality while intentionally distancing itself from generic, ordinary alternatives.

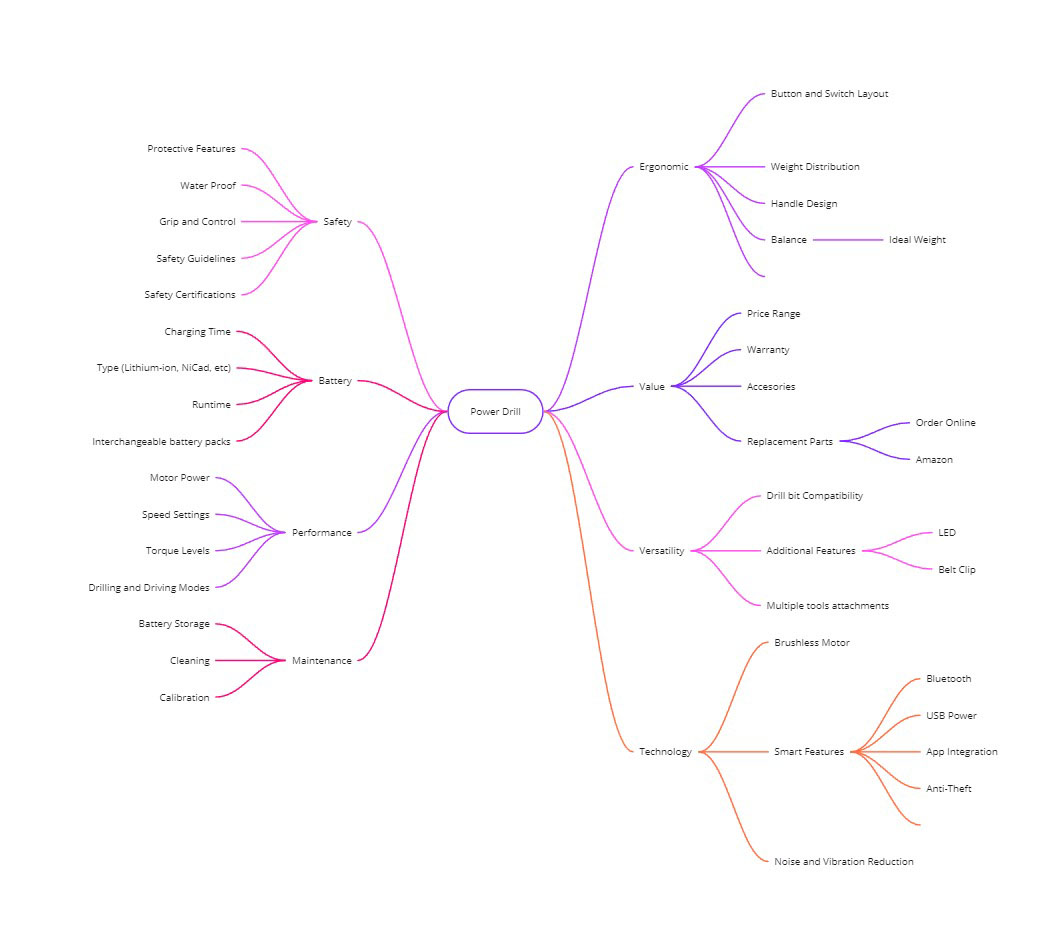

Mind Map

In developing this innovative drill, a comprehensive mind map was employed to identify and organize key features, requirements, and differentiating factors. This structured approach allowed me to explore essential aspects like battery technology, safety, ergonomic design, performance, and versatility, ensuring a well-rounded product. The mind map also highlighted unique challenges faced by the users, providing valuable insights that helped me craft a tool specifically suited for demanding environments and prolonged use.

User Personas

The user personas developed for this drill focus on carpenters and every day people who value reliability, durability, and ergonomic design in their tools. These personas represent individuals who work at home, office or in challenging conditions offering advanced features tailored to their specific trade requirements.

Observational Research

Man Gripping the Drill and Removing Screws:

- Observation: The grip is firm and secure while removing screws, emphasizing the importance of an ergonomic handle that reduces hand strain.

- Angle Variations: Different angles highlight the need for a balanced weight distribution and an adjustable, lightweight design that adapts to various positions.

Woman Using the Drill Overhead:

- Observation: The user extends her arms to place screws into a high door, revealing the challenges of holding the drill steady overhead. This underscores the need for reduced weight and better control in prolonged use.

- Multiple Angles: Other angles show how awkward positions can exacerbate fatigue, highlighting the importance of ergonomic handles and trigger placement.

Time Efficiency:

- Observations: When observing both the man and woman using the drill to remove and install screws, it was evident that the lightweight design enabled faster screw installation and removal. The ability to adjust speed easily meant that tasks requiring varying torque levels could be completed more quickly than with comparable drills.

User Feedback:

- Observations: Direct feedback was collected from the users regarding comfort and perceived effectiveness. The users appreciated the ergonomic handle and balanced weight distribution, which significantly reduced wrist strain and allowed for sustained use in awkward positions. However, both users suggested adding more cushioning to the grip to further minimize fatigue.

Comparative Analysis:

- Observations: When compared to competing drills, our drill demonstrated superior performance in terms of maintaining torque at different angles, particularly overhead. It was also noted that the adjustable speed control allowed more precise adjustments than other models, providing better control and reducing stripping of screw heads.

Environmental Factors:

- Observations: Testing in different environments revealed that the drill maintained consistent performance even in high-humidity conditions. The silicone and epoxy seals provided excellent water resistance, ensuring that the drill remained reliable despite moisture exposure. Additionally, the LED lighting feature proved beneficial in low-light conditions, allowing users to work safely.

Fatigue Analysis:

- Observations: After prolonged use, users indicated minimal fatigue due to the lightweight construction and comfortable handle. While crouching and kneeling, the design ensured proper balance, reducing strain on the back and wrists. The handle’s ergonomic shape and non-slip grip contributed to steady control even with sweaty hands.

Additional Observations:

- On Knees and Crouching: Working at low heights requires a flexible design that remains balanced while kneeling or crouching, preventing back and wrist strain.

- Awkward Grips: At certain angles, users may hold the drill awkwardly, stressing the need for a design that promotes a firm grip regardless of hand orientation.

- Variable Speed Control: Observing users switch between different screw types points to the importance of a versatile, easily adjustable speed control system.

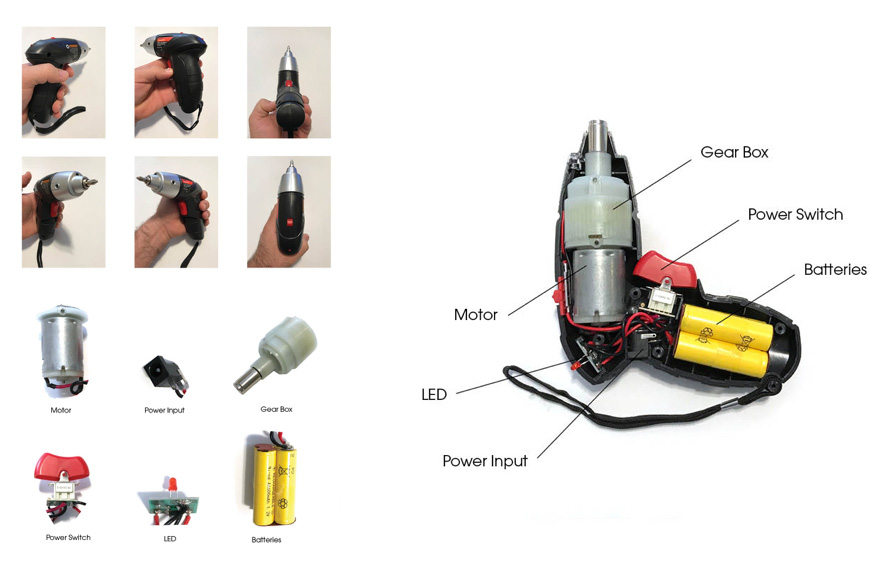

Product Analysis

In the image below I showcase a disassembly of a drill, revealing its internal components. This breakdown provides valuable insights into each part’s function, helping me identify areas for improvement in the design and ensuring that future iterations achieve optimal performance, durability, and ease of maintenance.

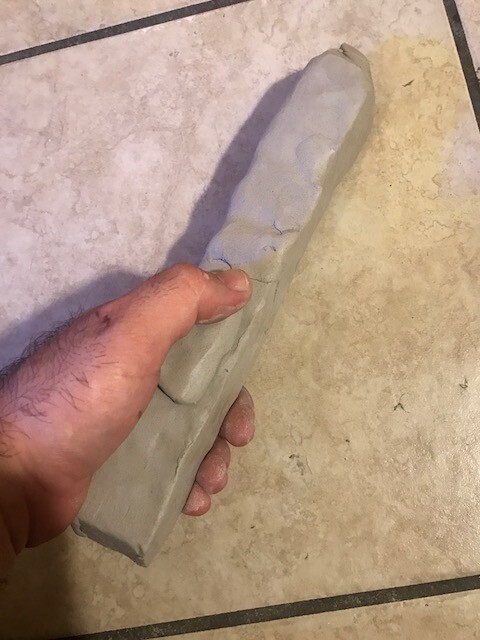

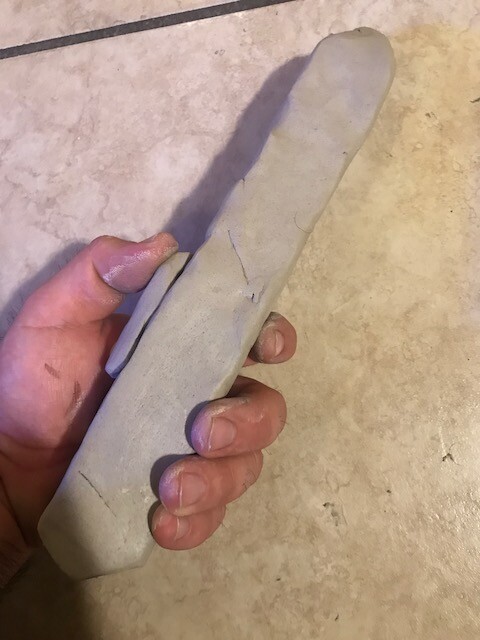

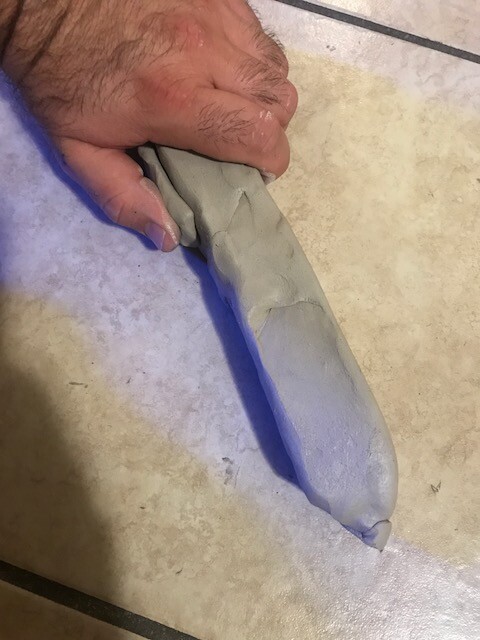

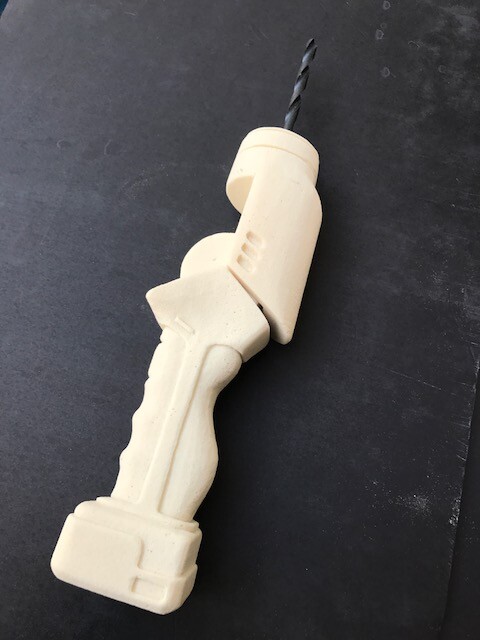

Ergonomic Clay Studies

The Ergonomic Clay Studies section documents a hands-on approach to finding the ideal drill handle shape. Through molding and testing different shapes and sizes using clay, various grip styles and ergonomic configurations were explored to ensure optimal comfort, secure handling, and reduced strain. These clay prototypes provided crucial insights into creating a handle design that offers a natural fit and enhances control, even during extended use.

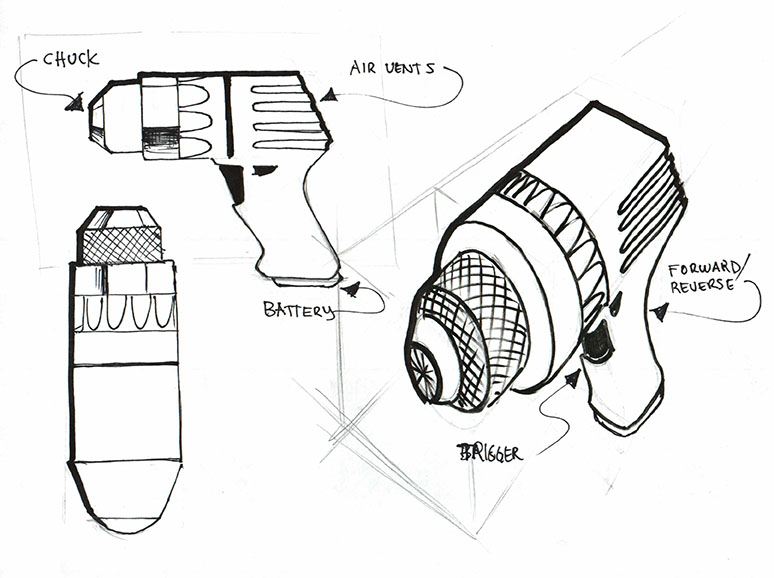

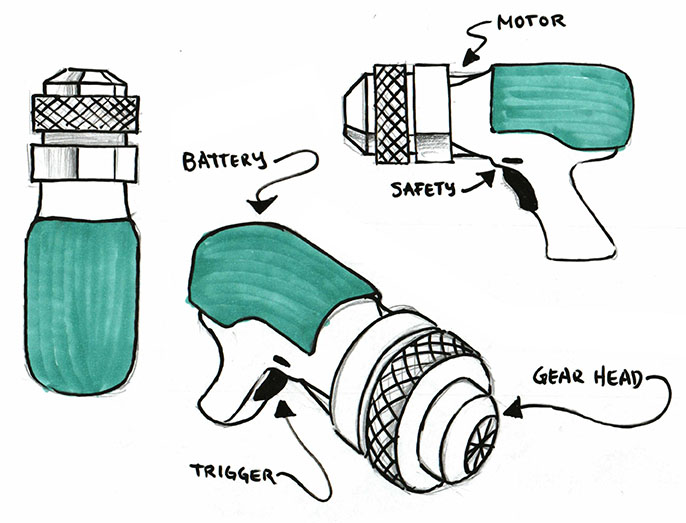

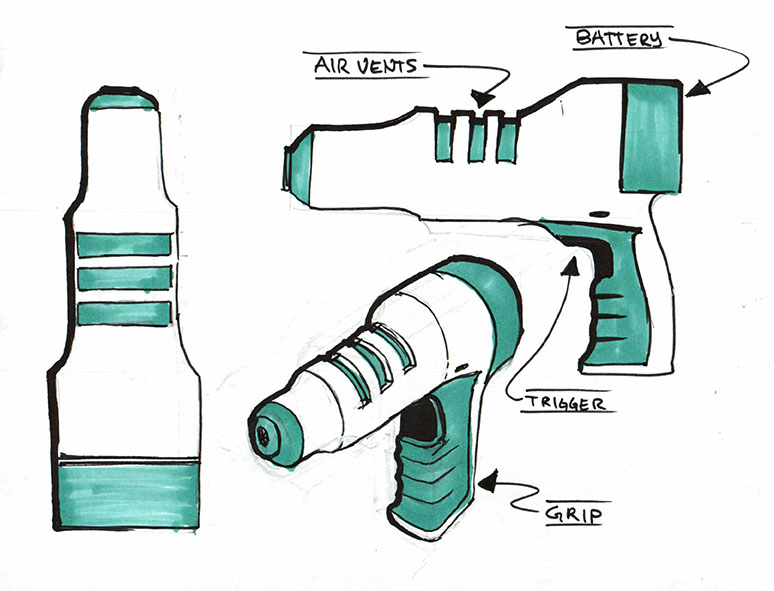

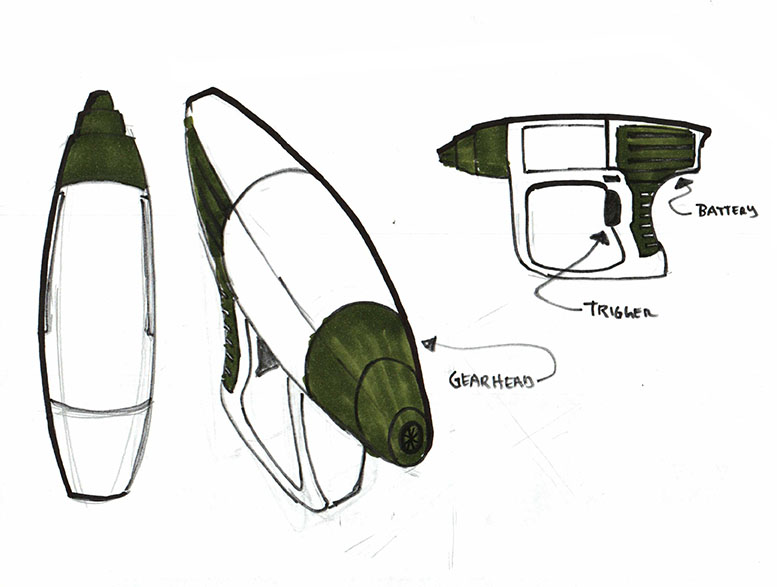

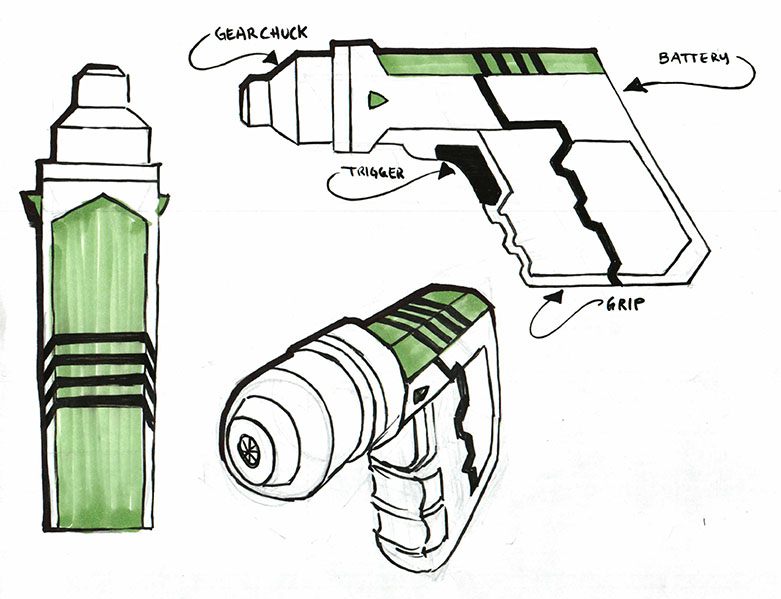

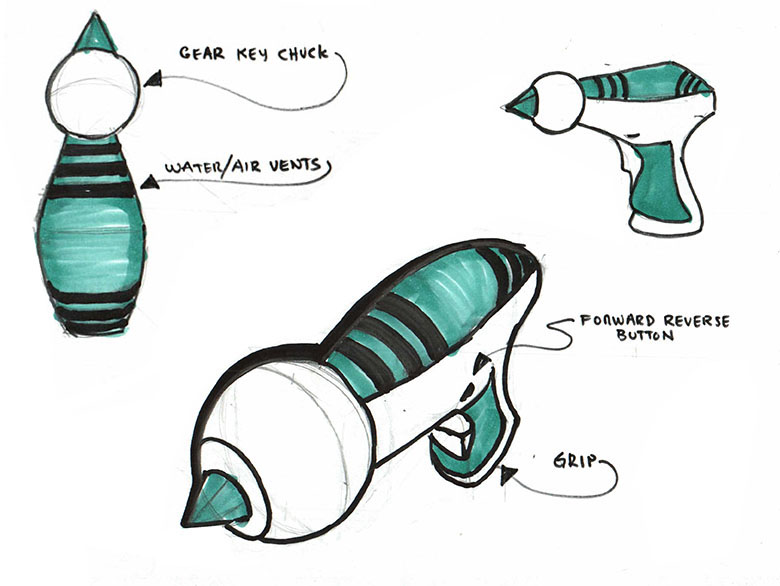

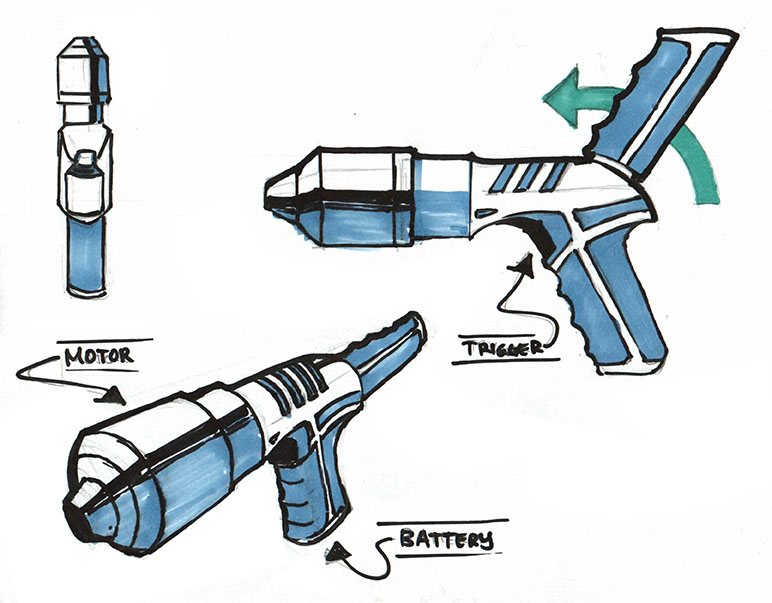

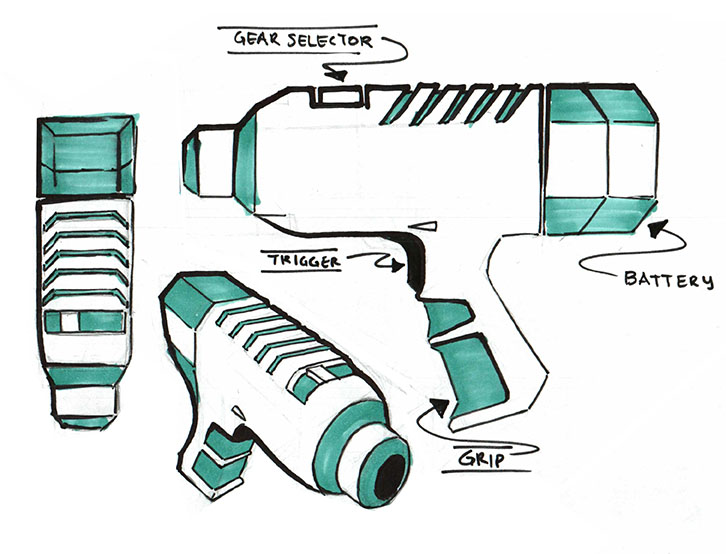

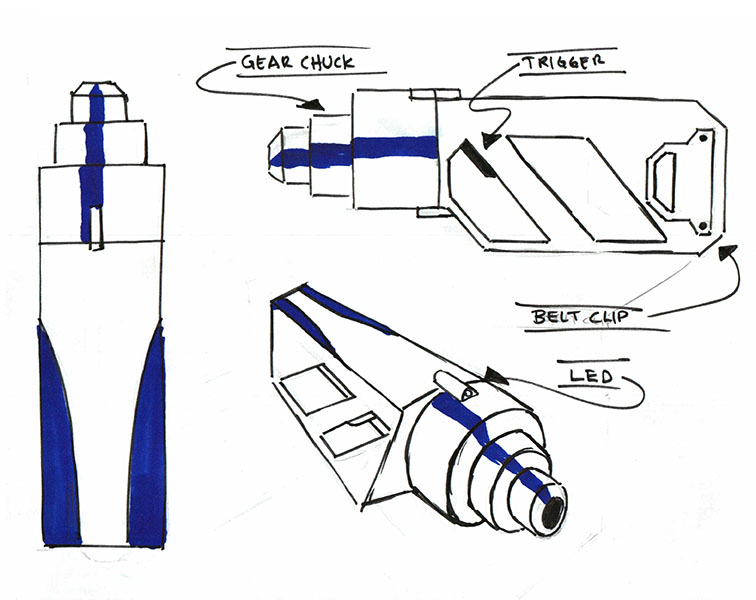

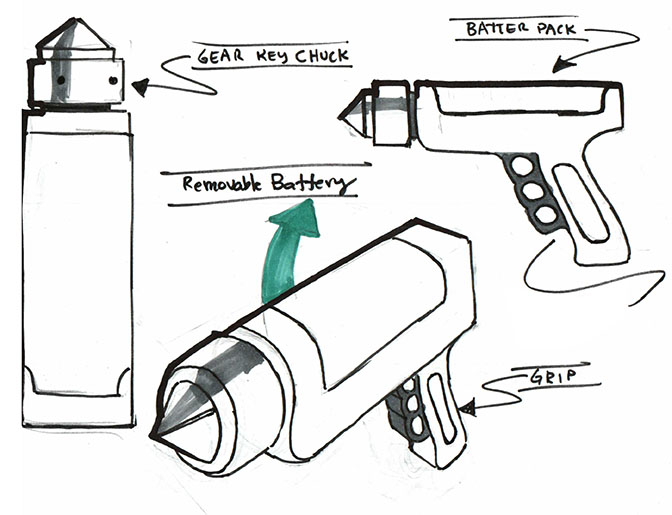

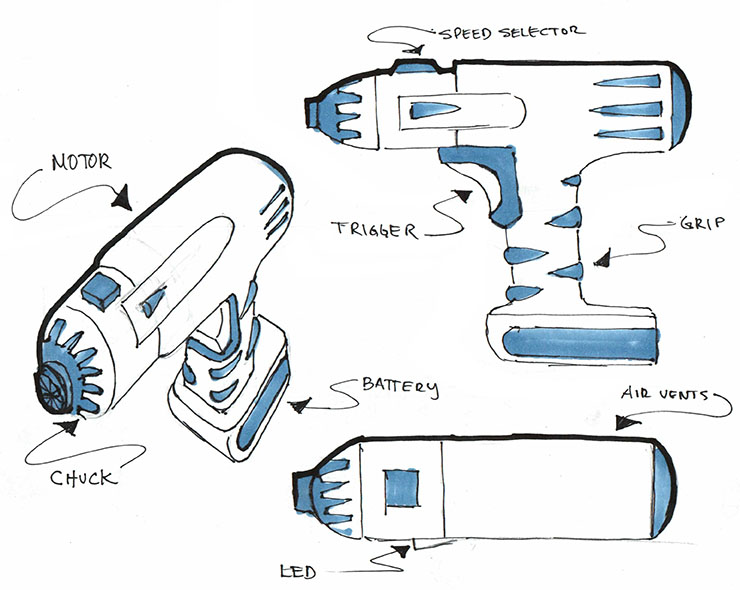

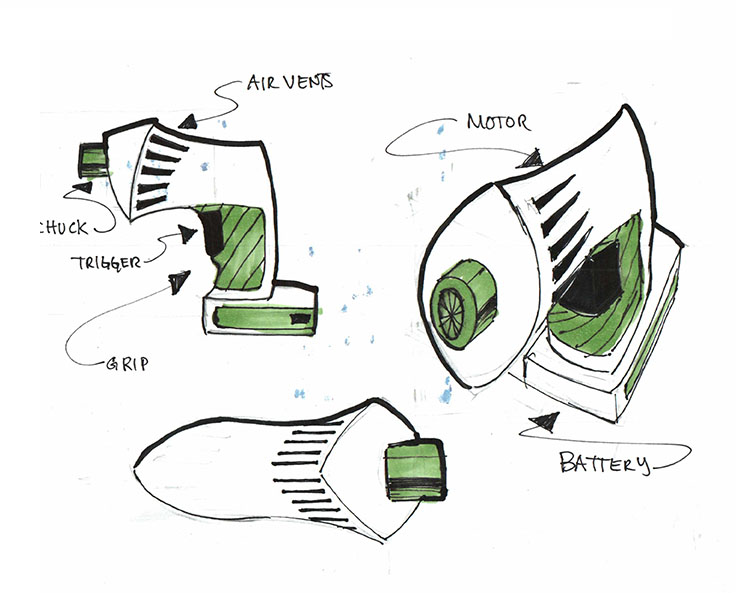

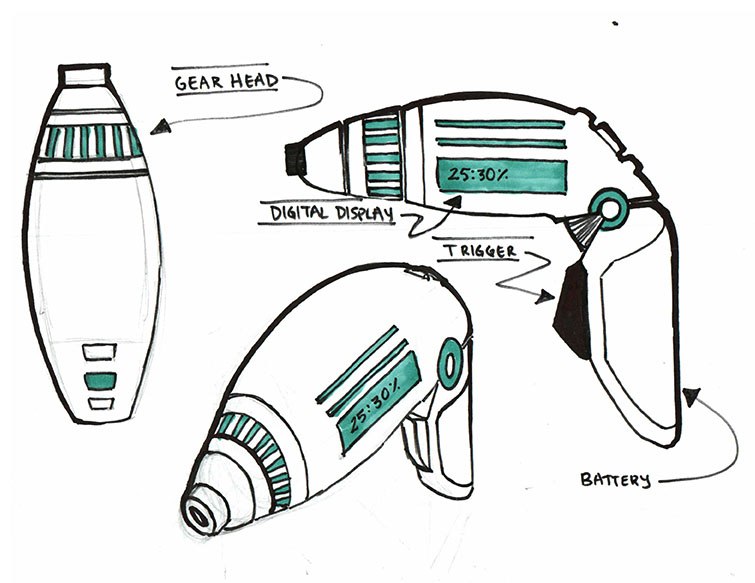

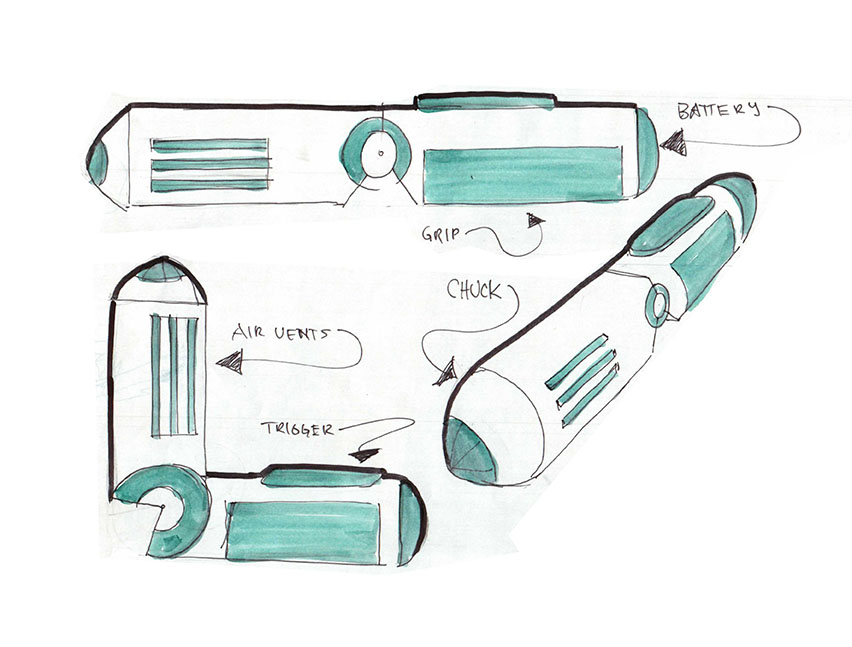

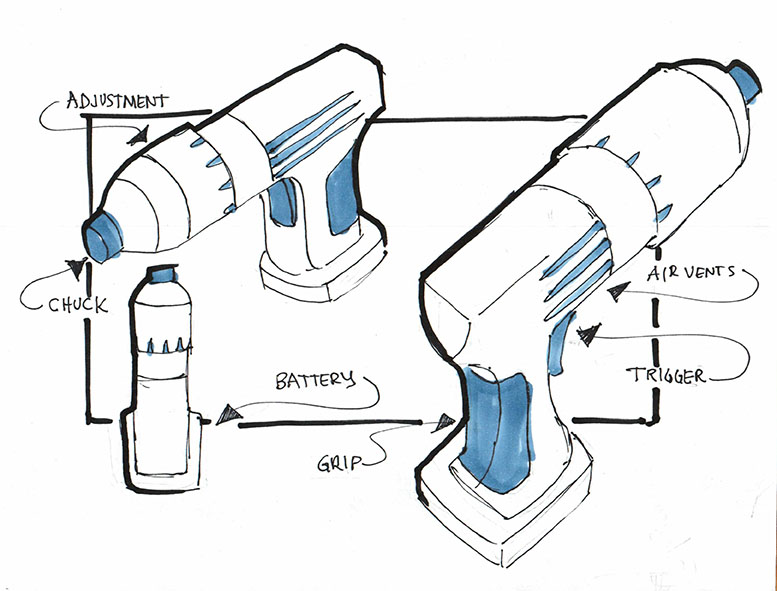

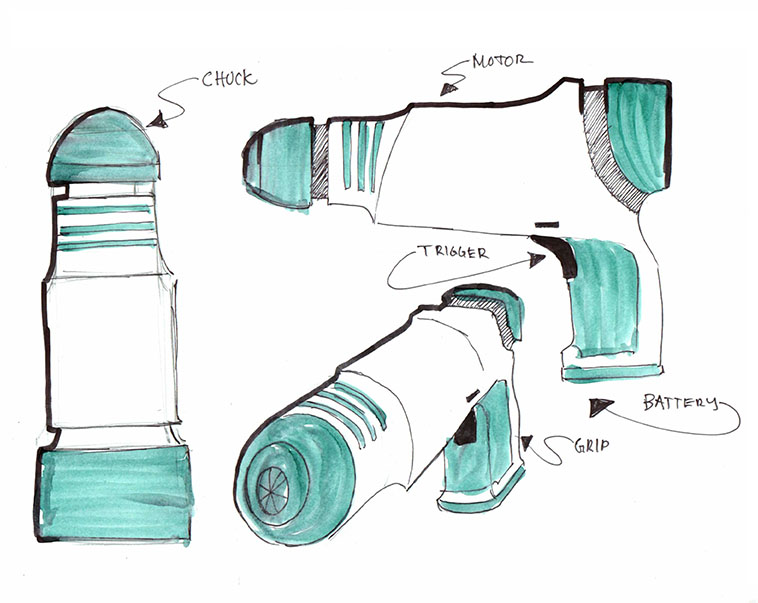

Concept Sketches

The Concept Sketches section showcases 16 design explorations that experiment with various shapes, features, and configurations. Each sketch offers unique insights into innovative design possibilities, emphasizing ergonomics, weight distribution, and functional enhancements to ensure the drill delivers optimal performance, user comfort, and style.

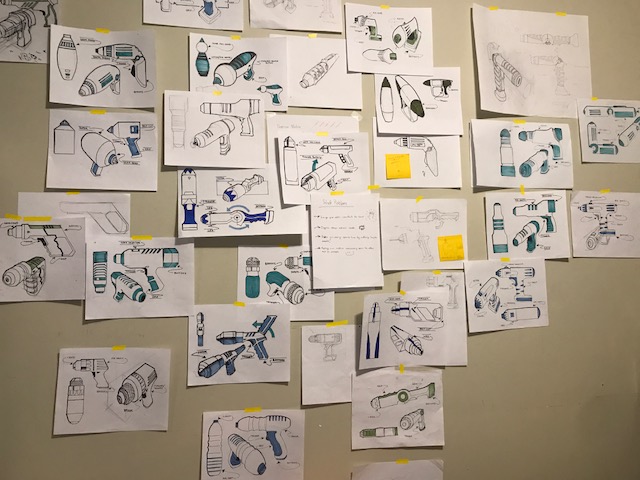

Reviewing Concept Sketches

In the Reviewing Concept Sketches section, all 16 sketches are displayed on the wall for a comprehensive evaluation. This process facilitates critical analysis of each design, allowing me to identify the most promising concepts based on ergonomic features, user feedback, and functionality. By visually comparing the sketches side by side, I refine ideas, identify potential improvements, and prioritize elements that align with the project’s core objectives to ultimately deliver a superior, user-centric drill design.

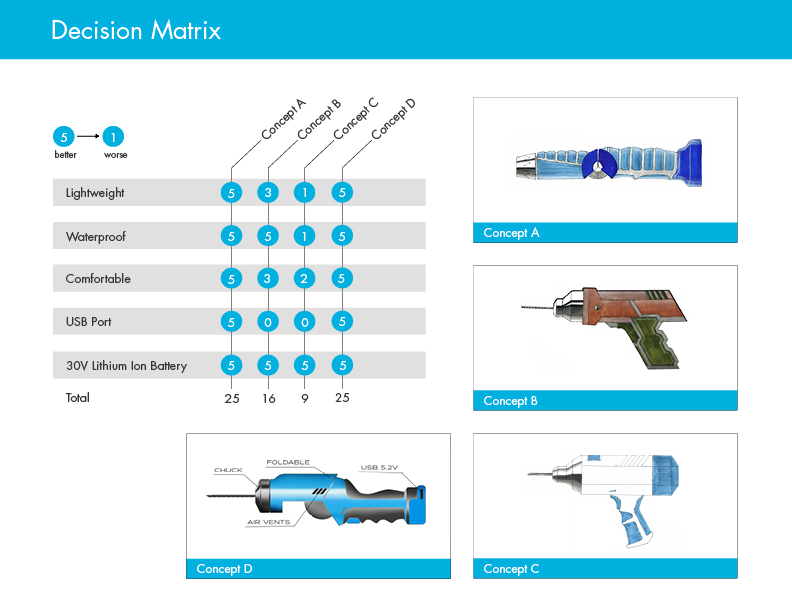

Decision Matrix

In the Decision Matrix concepts A through D were evaluated against key criteria: lightweight design, waterproofing, comfort, USB port inclusion, and a 30V lithium-ion battery. Concepts A and D both achieved the highest scores with 25 points each, excelling in lightweight design, comfort, and battery performance. Concept B scored 16 points, lacking some advanced features like USB port integration and full waterproofing. Concept C, scoring 9 points, prioritized other aspects but ultimately did not meet all the requirements. This matrix provides a clear comparison, allowing us to prioritize Concept A and Concept D for further development while addressing areas that require enhancement in other designs.

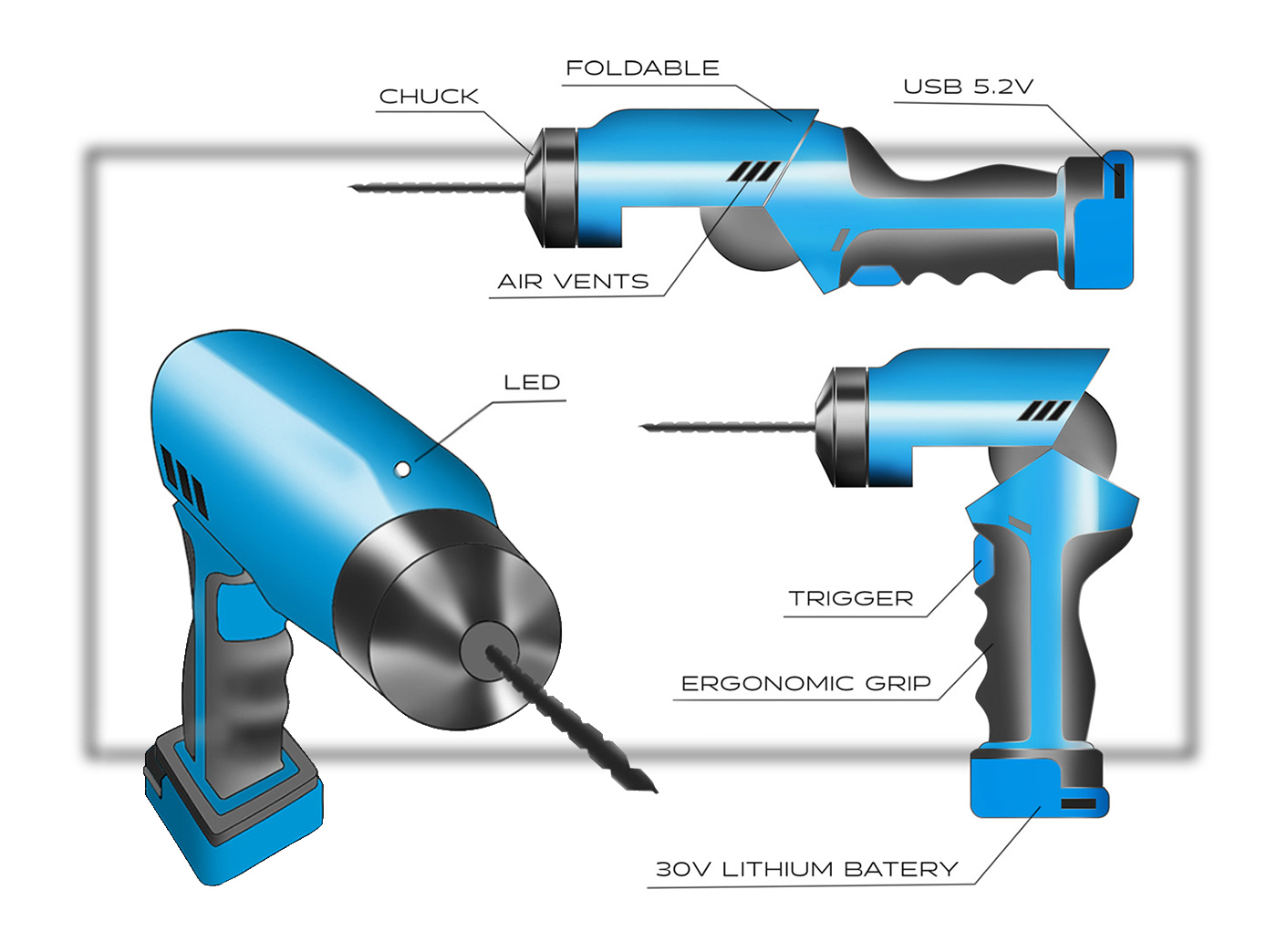

Refined Design

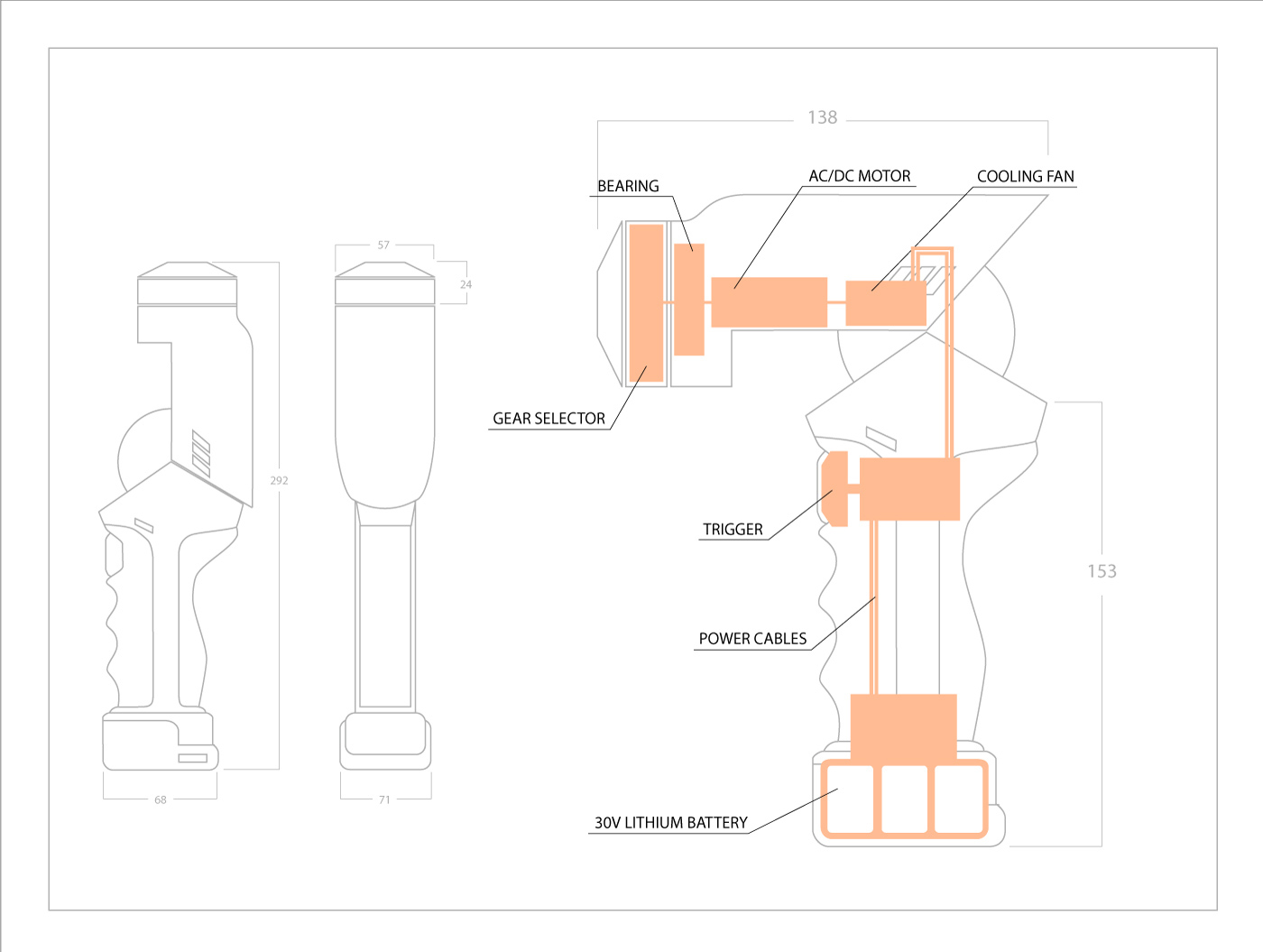

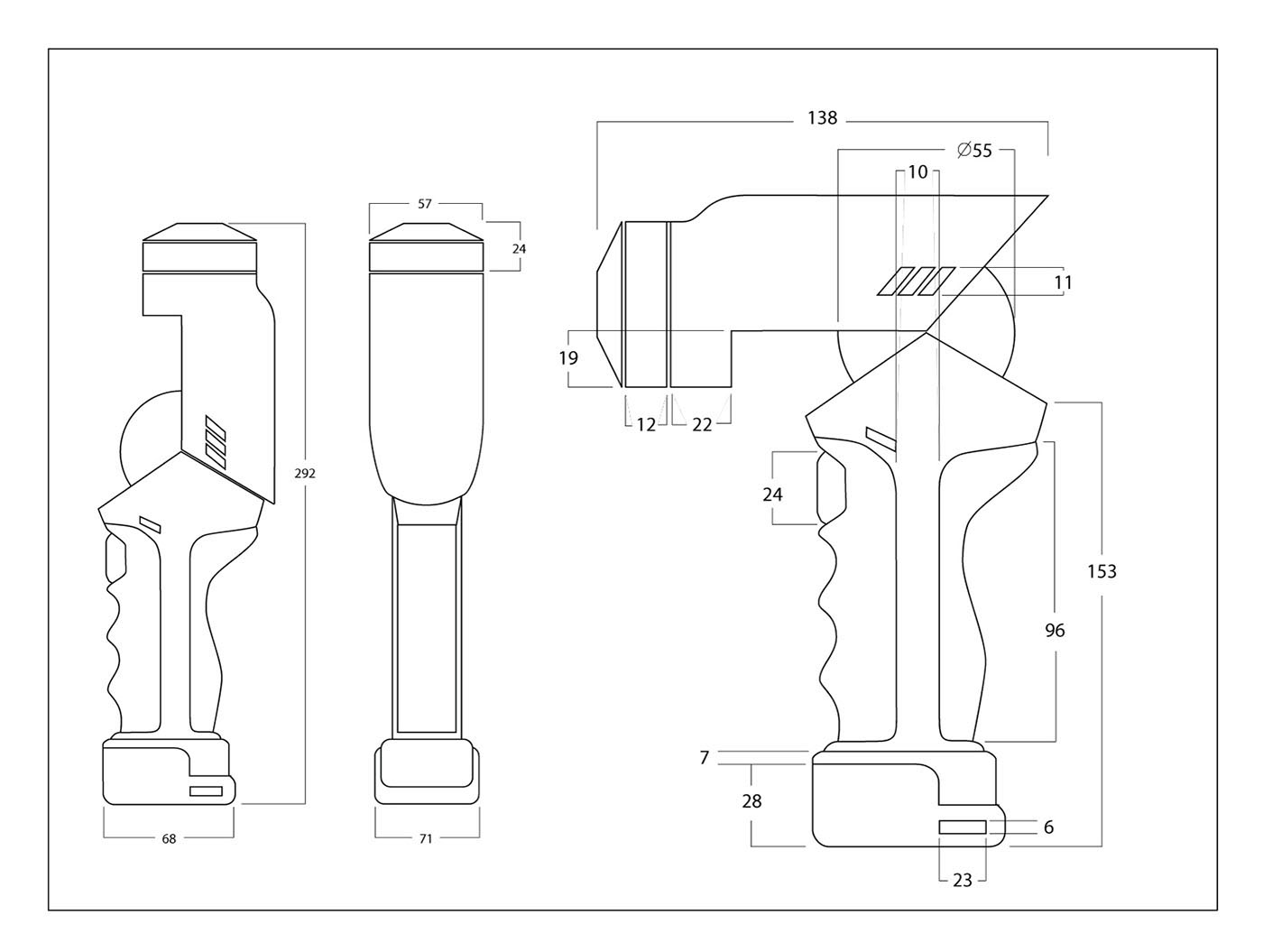

Component Layout Drawing

Design Control Drawing

Polyurethane Sketch Model

The images below reveal the progressive development of the drill as it is meticulously carved out of polyurethane. This stage offers a tangible prototype that allows for refining the design’s ergonomic features and ensuring that the final product delivers an optimal grip, balanced weight, and aesthetic appeal.

Final Model

The drill in its fully painted and completed form, embodies the culmination of extensive research, conceptual exploration, and iterative design. The ergonomic handle, shaped through clay studies and polyurethane models, is evident in its natural grip and lightweight feel. Its water-resistant construction, enhanced with silicone and epoxy sealing, ensures reliable performance in wet and demanding conditions. The 30V lithium-ion battery delivers consistent torque, while USB ports and a 110V socket add versatile charging options. Concept sketches and the decision matrix guided the product’s evolution, ensuring that the final design prioritizes comfort, functionality, and style.

Reflections

In reflecting on this project, the process of researching, conceptualizing, and refining ideas for the drill proved essential in creating a professional-grade tool that excels in ergonomic design, durability, and technological features. Observational studies and the decision matrix were instrumental in identifying the optimal features to incorporate. Moreover, user feedback revealed specific requirements that informed the final design, resulting in a tool specifically tailored for carpenters working in demanding environments. The journey from sketches to prototypes to a finished product demonstrates the importance of an iterative, user-centered approach that prioritizes innovative solutions for real-world challenges.